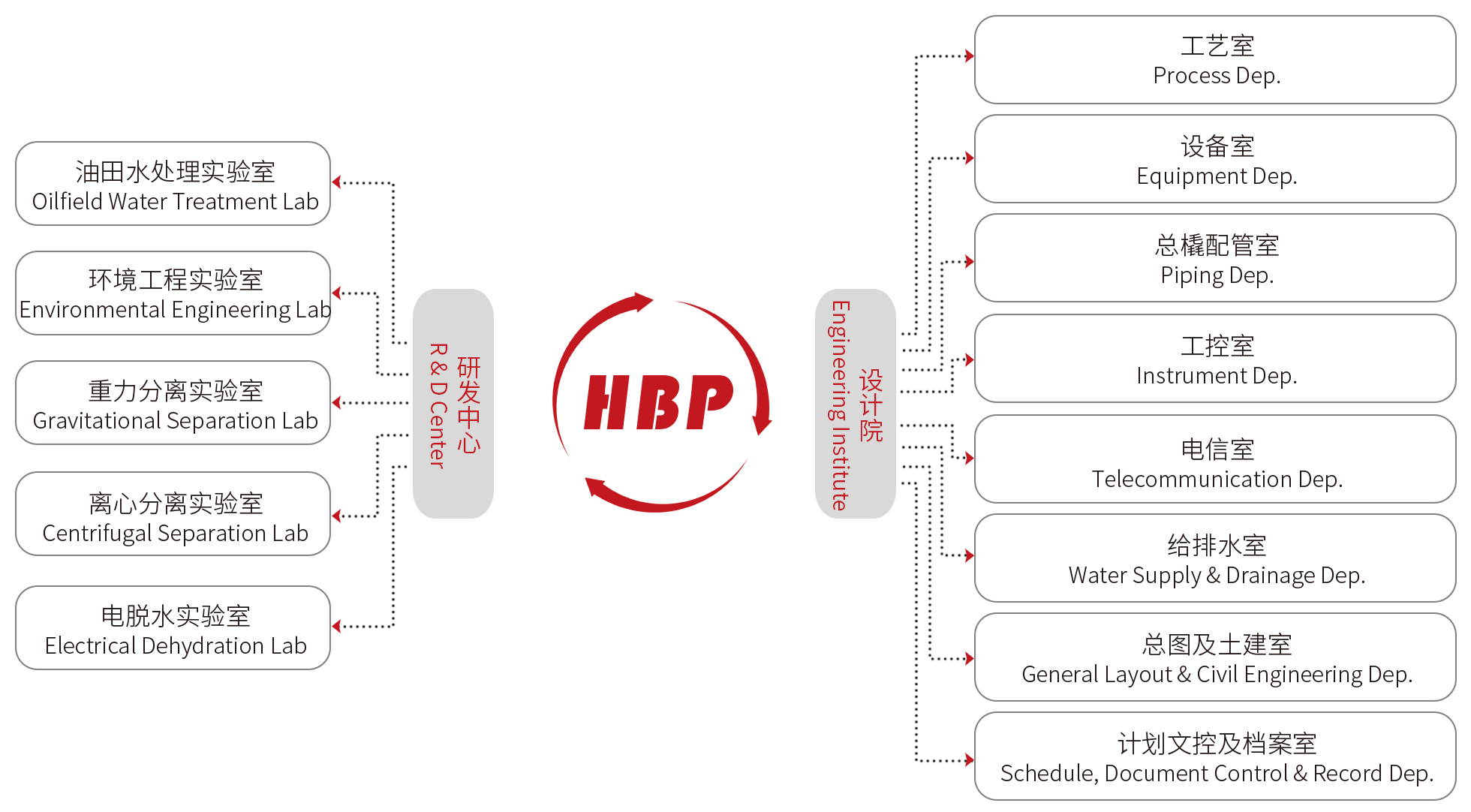

Introduction of design ability

▲ Adhering to the sustainable development path of technological innovation, dedicated to providing efficient, energy-saving,environmental protection integrated solutions and complete equipment for petroleum industry customers

▲ Collaborating with internationally renowned specialized companies, scientific research institutes and petroleum universities

▲ Professional, dedicated, innovative and experienced talent team

▲ Strong hardware and software strength and first-class R & D personnel

▲ At present, HBP has owned more than 30 invention patents, 60 new utility model patents, more than 100 software copyrights, more than 50 proprietary technologies, forming a complete core technology system

Typical performance

Project Brief: Kazakstan North Buzachi Natural Gas Processing Station EP Project, processing scale: 46.6X104m3/d, including natural gas compression, separation and purification, molecular sieve dehydration, transport metering system andauxiliary facilities.

Design time:June – December, 2011

Production date: June, 2012

Project Brief: Iraq Missan Natural Gas Sweetening EPC Project, two trains; for each train, the natural gas processing capacity: Phase I: 500,000 m3 per day; Phase II: 1,100,000 m3 per day. The feed gas contains 4.82% CO2 and 2.3% H2S. After processing, the content of CO2 is less than 2.5% and the content of H2S is less than 7.5ppm.

Design time:March – August, 2014

Estimated production date: April, 2015

Project Brief: Peru PERENCO Company 54 sets of on-shore oil and gas processing equipment, including flare, metering skid, instrument air skid, various pump skids, hot oil heating skid, etc.

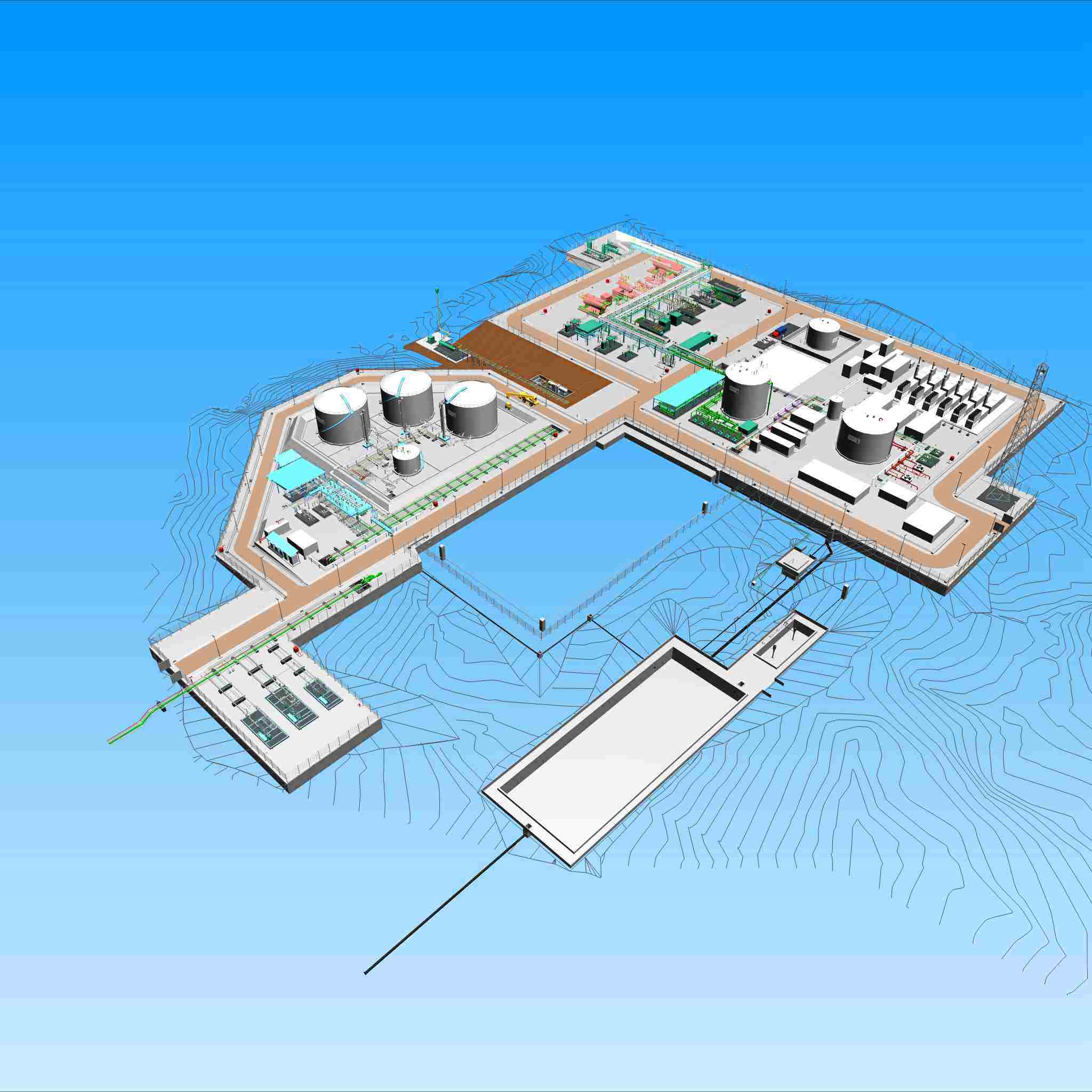

Project Description: The EP project of Emir Oil and Gas Treatment Station in Kazakstan has 600,000 m3 of natural gas processing capacity per day and 600,000 tons of crude oil processing capacity per year. Natural gas treatment devices include natural gas compression, separation and purification, desulfurization, molecular sieve dehydration, low-temperature degassing, LPG recovery and metering system. The crude oil treatment device includes separation and purification, electric desalting and dehydration, crude oil stabilization and storage system.

Design time: June 2012-June 2014

Estimated production time:September 2015

Project Description: EP project for natural gas desulphurization in Atyrau, Kazakhstan: to treat crude oil associated gas containing H2S and methanethiol, to produce qualified commercial natural gas and condensate by technologies such as gas compression, amine sweetening, low temperature drying dehydration, and stable condensate; Sulfur is recovered through LO-CAT technology from sour gas H2S after amine sweetening to produce commercial sulfur.

Project Description:Kozhasai Natural Gas Treatment Project produces qualified commercial natural gas, LPG, stabilized light hydrocarbon and granular commodity sulfur.These are produced by using alcohol amine desulfurization, molecular sieve dehydration and mercaptan, DHX light hydrocarbon recovery, and super Claus sulfur recovery process. The treatment capacity of the device is 90x104sm3/d, with 2.46% of H2S in feed gas, 1270ppm of mercaptan and the operating pressure being 4.0MPaG. H2S contained in commercial gas ≤7mg/m3, with total sulfur content ≤16mg/m3.